In powder coatings, wax additives containing PTFE have been used for decades to provide a number of unique properties, such as enhanced surface protection; scratch, mar and abrasion resistance; reduced coefficient of friction (CoF); and to act as a texturing agent. Newer PTFE-free wax additives are being developed at a faster pace as formulators look for alternatives to using PTFE in their powder coatings.

While PTFE provides many benefits; temperature and chemical resistance; and, non-stick properties, it also faces growing regulatory pressure because of the potential hazards of the by-products that can be generated when it is produced (namely PFAS components like perfluoro octanoic acid (PFOA) and perfluoro-octane sulfonic acid (PFOS)).

Wax additives have more recently become a focus area in the search to replace traditional PTFE materials with PTFE-free alternatives. PTFE-free alternative wax additives use different raw materials that function like PTFE, but without the potential hazards and regulatory challenges that come with PTFE.

Lubrizol’s PTFE-Free Solutions

Lubrizol’s technical team has been working on the development of PTFE-free wax additives for several years, with several commercially available products and multiple products in development. Each of these PTFE-free wax additives demonstrate similar properties to PTFE-containing additives.

Lubrizol used extensive experience in the powder coatings market to develop a new family of PTFE-free wax additives for powder coatings. These developmental products have proven to deliver comparable or better performance for surface protection when tested against traditional products containing PTFE. Following are the results demonstrating that these materials can produce attractive, high gloss coatings with strong surface protection.

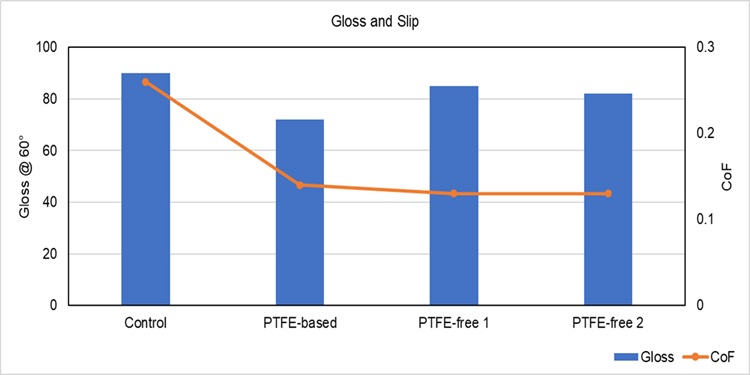

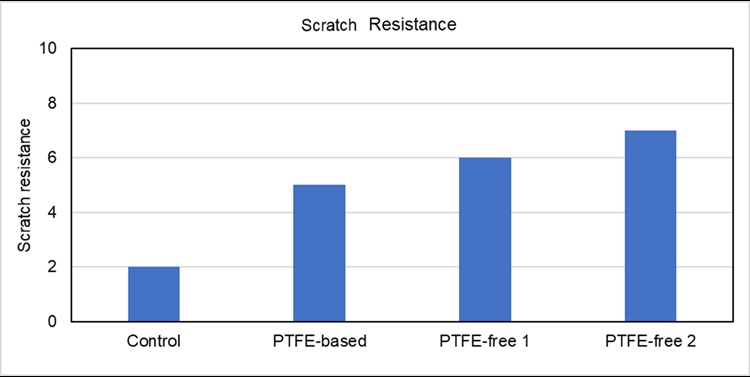

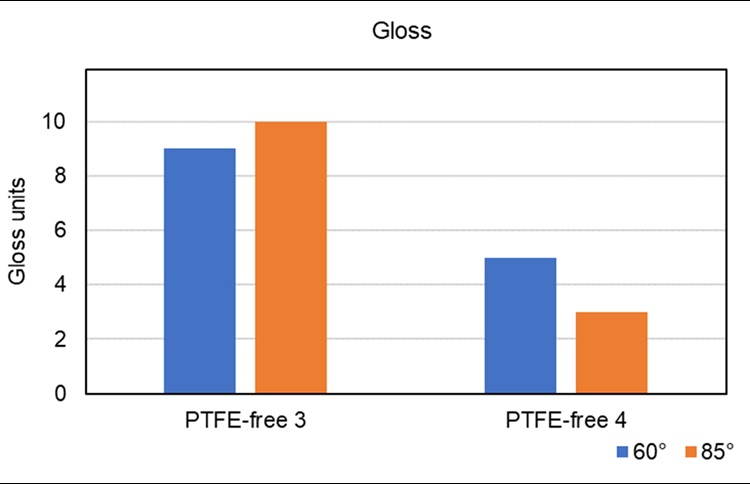

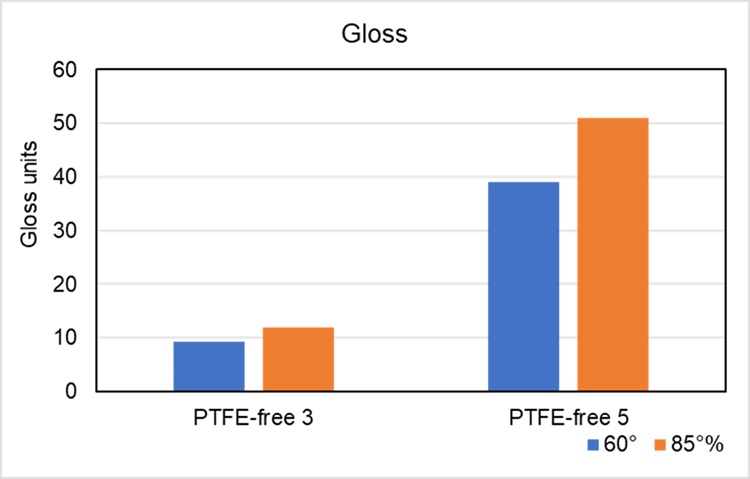

The graphs below show the test results of product performance in black polyester/HAA with a 2% addition rate of wax additives, curing conditions of 180˚C for 10 minutes and 70-100 μm film thickness. The reference sample contains PTFE-based wax additive and was used as a benchmark. The control is a powder coating with no wax additive.

Gloss and Slip

The results show that the gloss with PTFE-free wax additives slightly better than the PTFE-based while the CoF/slip is comparable.

Scratch Resistance

Scratch resistance results were visually evaluated with respect to wear using a scale rating of 0 to 10, where 0 is complete scratch (0=very poor) and 10 is no scratch (10=excellent). Coatings with no wax showed poor performance. The formulations containing waxes demonstrated high scratch resistance. From the results, both formulations with PTFE-free wax additives perform similar to or slightly better than the formulation with PTFE-based additives.

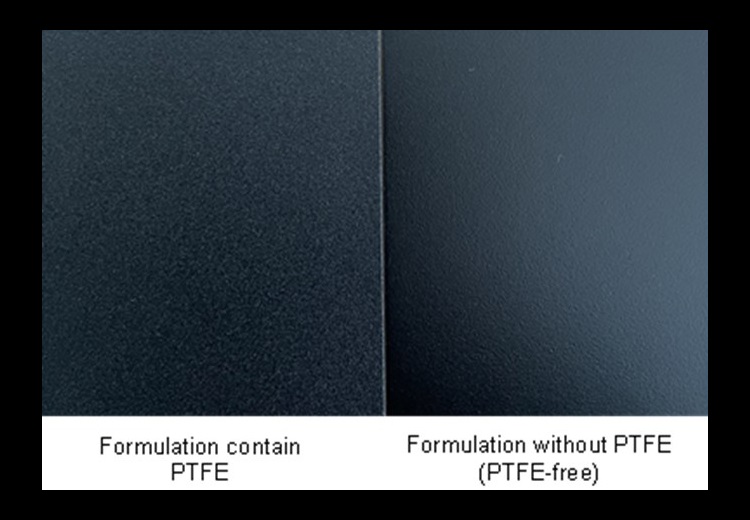

Fine Textures without PTFE

One of the unique features of powder coating is its ability to deliver a textured finish that can range from fine to rough. These textured finishes are used in a variety of markets, from industrial to decorative coatings to provide a unique appearance and a tactile response to touch, as well being able to mask small imperfections due to the lack of a smooth surface finish.

PTFE additives have traditionally been used to create a fine surface texture. It can be challenging to create these fine textures without using PTFE. Lubrizol has developed wax additives that enable powder coatings to deliver similar fine textures without the need to use PTFE, acting as a texturing agent without interfering with the extrusion to provide controlled and reproducible texture.

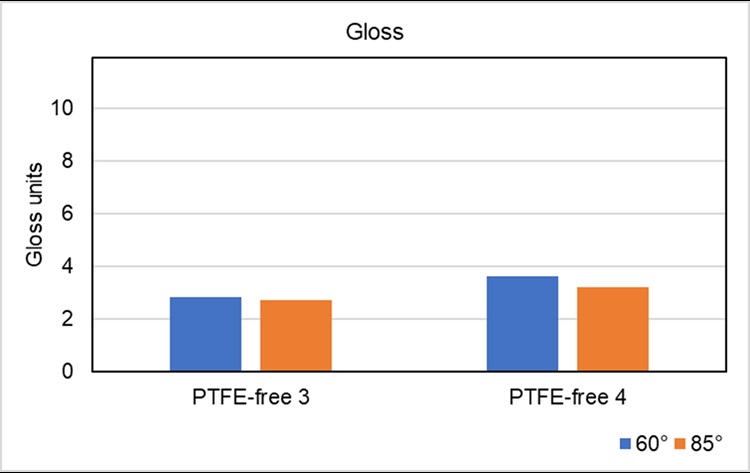

Matting Efficiency

Matting efficiency results are system dependent. It depends on the resin system particle size, filler, etc.

The 3 graphs below show the matting efficiency with PTFE-free 3, PTFE-free 4, and PTFE-free 5 wax additives at various addition levels. Various gloss and texture effects are capable with similar effects compared to a coating containing PTFE.

In addition to these PTFE-free wax additives for powder coatings that are being developed, Lubrizol offers commercially available PTFE-free technologies for powder coatings under the Lanco™ and PowderAdd™ Surface Modifiers brands. These products provide scratch and mar resistance while reducing coefficient of friction (COF) comparable to traditional PTFE-based wax additives. Lubrizol also continues to develop PTFE-free texturing additives for powder coatings.

Contact us to learn more about our PTFE-free wax additives for powder coatings.

.