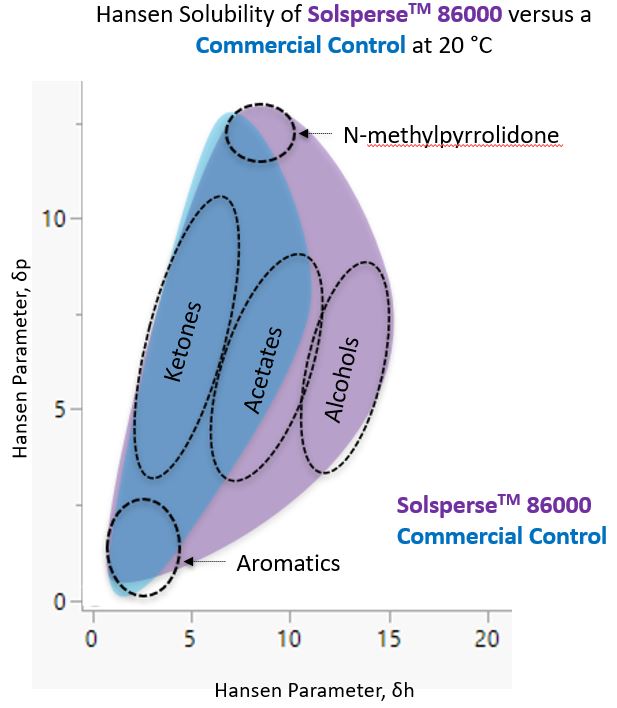

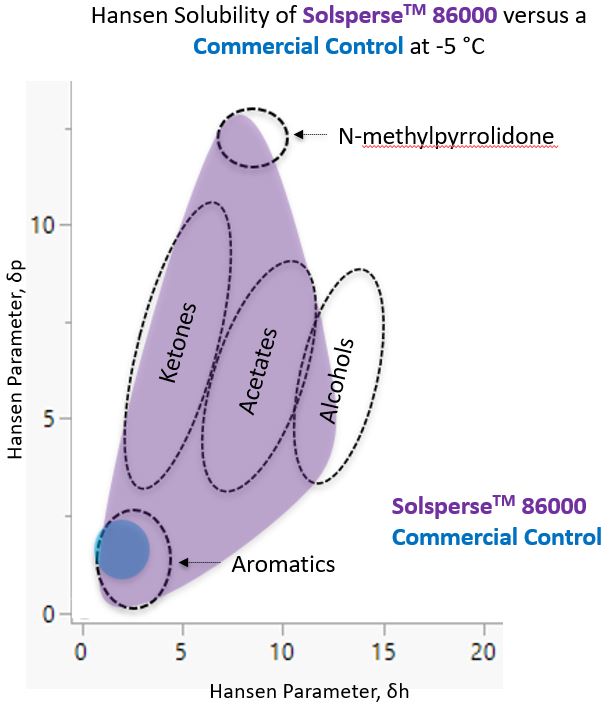

For a dispersant to work in a formulation—any coating formulation—it must be soluble in the solvent in which a pigment is being dispersed. The dispersant must fully dissolve in the formulation or there will be inefficient additive performance and the formulation will fail. Therefore, the right dispersant is critical to the achieving an effective formulation.

Most dispersants are sold in the solvents in which they work most effectively. However, this can be somewhat limiting for the formulator, especially for systems where minimum or no solvent is desired, such as for low VOC coatings. For this reason, 100% active dispersants can deliver some outstanding benefits. Some applications, such as UV, have to use 100% active because diluent solvents are incompatible with their systems.

One downside is that conventional 100% active dispersants can be very viscous, potentially requiring the need to be heated for use to improve mobility. This is an added expense and step and if there aren’t facilities to warm the dispersant, the formulator could be forced to buy the diluent grade.

However, as a market leader of dispersants for solvent-based applications, Lubrizol continues to innovate 100% active dispersants with a lower viscosity, so they are easier to handle. Lubrizol offers an extensive portfolio of 100% active Solsperse™ Hyperdispersants and uses solubility parameters to help customers understand the suitability for their formulations.

Solubility of Solsperse™ 86000 at 20 °C. Hansen solubility parameters help predict if one material will dissolve in another and form a solution.

Solubility of Solsperse™ 86000 at -5 °C. Hansen solubility parameters help predict if one material will dissolve in another and form a solution.

Solsperse™ 86000 Hyperdispersant is one example from Lubrizol’s product line of 100% active dispersants. It is a 100% active pourable dispersant giving solubility across a wide polarity of solvents from aromatic, ester, acetate to alcohol. It is especially suitable for UV applications using polar monomers.

Formulation Freedom

As Solsperse 86000 has excellent compatibility across a wide range of solvents, formulators can use the dispersant in many coating or inks applications with the ability to source whatever diluent they want.

Environmental Footprint

When only the 100% active material is shipped, the need to transport solvents is eliminated. The diluents can be added added locally, reducing impact on the environment.

Contact us to learn more about our 100% active polymeric dispersant technology.

Subscribe to Our Blog