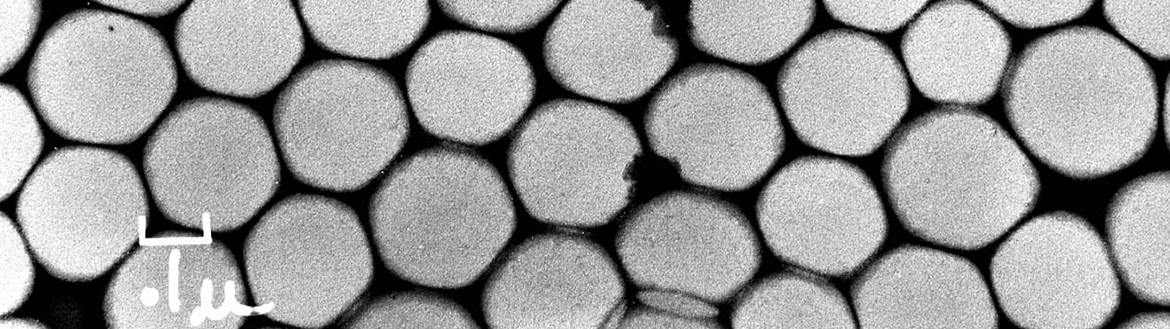

An emulsion polymer is a colloidal dispersion of discrete polymer particles with a typical particle size range of 0.05–0.5 microns in water. To get an idea of just how small these particles are, think of the period at the end of this sentence. It’s pretty small, but a sphere this size could hold 10 billion latex particles. Not surprisingly, these particles are only visible with powerful microscopes.

Particle size can be measured using laser light scattering methods. At Lubrizol, we measure particle size of most polymer emulsions during production in our plants to ensure particle size specs are met.

Particle size is also about distribution, which means not all particles are the same exact size. If a measurement is shown as 0.1, it’s an average particle size. Some particles might be .08 while others might be 0.12. Particle size and their size distribution impacts a number of coating properties, including viscosity, water resistance, film clarity, mechanical stability, gloss, and more.

The distribution—think broad or narrow—affects viscosity and rheology. At a given average particle size, a broader particle size distribution (PSD) correlates with significantly decreased latex viscosity and more Newtonian rheology.

Shear thinning rheology means that the harder a coating is mixed, the thinner it gets (think ketchup). Newtonian rheology means the viscosity will remain unchanged with mixing (think water). These properties can matter in some applications.

Rheology

Particle size distribution can affect the shear rheology, not just for the polymer, but also for the end product. Shear thinning rheology can be seen when spraying a coating. To spray easily, the viscosity should be low during shear. But once on the substrate, the viscosity ideally should be higher to avoid dripping or sagging. Further, penetration into some substrates can be controlled by the shear rheology of the coating or ink.

There are multiple other applications where the opposite effect is desired, with flatter viscosity versus shear being needed. For example, printing a design on paper at high speed may spatter ink if the viscosity thins too much during application.

Broad PSD vs. Narrow PSD

A product can be designed that has narrower or broader particle sizes. With the exact same polymer composition, different properties can be created by controlling the particle size, along with a number of other factors. How a product is designed can deliver very different properties.

In digital printing applications, narrower particle size distribution, and especially avoidance of large particles, can be important. This is because larger particles can cause print head build-up problems.

Wood floor coatings are another example of how particle size can be significant. The particles can be made so small that when the coating is applied, it is essentially clear over the wood when wet. This is desired by some wood coating manufacturers for the painter or homeowner to be able to see the grain of wood as it is applied. For such an application, Lubrizol makes a small particle size product, so the coating is not opaque when applied. The smaller particle size helps deliver water resistance, gloss and more. Similarly, small particle sizes may be advantageous for applications in which penetration into substrates or smooth coating surfaces are desirable.

To learn more about particle size distribution and its impact on application properties or for help selecting the right polymer for specific needs, contact your Lubrizol account manager.

Subscribe to Our Blog