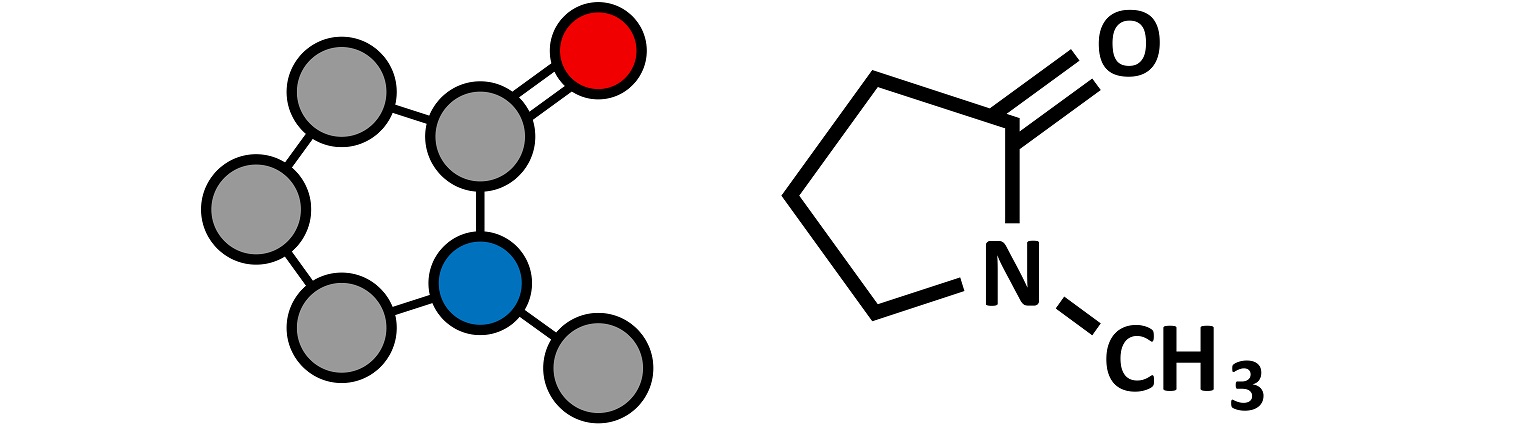

N-Methylpyrrolidone, also known as NMP or N-methyl-2-pyrrolidone, is a common co-solvent used in the creation of waterborne polyurethane dispersions (PUDs), which means it’s found in a range of products. NMP helps in processing PUDs and in the film formation of the applied polyurethane coating. NMP can also aid in substrate wetting, freeze/thaw stability and adhesion to some substrates, as well as acting as a microbicide in the wet phase.

NMP has been used as a co-solvent for many years because of its beneficial properties, but its negative properties have come under increasing scrutiny, leading to more regulatory pressure and consumer backlash. NMP has been shown to be a skin and eye irritant and have effects on body weight, liver, kidney, spleen and thymus. The U.S. Environmental Protection Agency (EPA) describes NMP as a developmental toxicant, closely linking it to developmental impacts, including miscarriages. NMP is considered a volatile organic compound (VOC) and is a California Prop 65 substance.

In Europe, NMP is considered a substance of very high concern (SVHC) because it has a classification of toxic to reproduction. NMP was added to the REACH restricted substances list in 2018, restricting its use in consumer applications to <0.3% starting in 2021, which is effectively a ban because NMP would have no functionality at this level in present consumer applications.

Free From NMP

One potential side effect of removing NMP from PUDs is that the finished formulation may not coalesce as well because NMP acts to help coalescence of the film. The film needs to coalesce before drying, or performance properties will suffer. For a formulator, the solution to this challenge will most likely be adjusting the amount of coalescents used in the formula. Coalescents allow paint to dry in one continuous film, not discreet particles.

Another side effect could be adhesion to low surface energy materials. NMP helps coatings stick to materials like plastic and other difficult-to-stick-to substrates. When NMP is removed, co-solvents, coalescents or adhesion promoters may need to be used to ensure the same level of adhesion.

When it comes to maintaining antimicrobial properties, formulators may need to change the biocide being used or add more of it to adequately protect their product—followed by running formulation challenge tests to look for the growth of microbes over time, which will indicate if the product is adequately protected. Challenge tests can last for several months, so that time needs to be taken into account in new product development.

The Benefits

Creating effective, quality NMP-free polyurethanes is entirely possible and is safer for formulators to use because of increasingly stringent regulations and VOCs. By removing NMP, finished products are generally lower in VOCs, which is one of the most important properties of a finished formulation and what formulators watch most as VOC limits keep going down across the country.

Lubrizol has worked with multiple formulators to develop NMP-free PUDs, using alternative solvents that aid in film formation and deliver the same benefits as NMP, but without the regulatory challenges. We can work with formulators of all sizes with starting point NMP-free PUD formulations or to collaborate on tailor-made solutions specific to unique needs.

Contact your Lubrizol account manager to learn more.