There are few forces in nature as destructive as fire. As evidenced by major wildfires in the United States, Greece and elsewhere over the past year, fire can be nearly impossible to control. The same is true on smaller scales, such as when fires happen in homes or businesses or automobiles. They are difficult to fight and can lead to the tragic loss of life, injury and significant property damage.

According to the National Fire Protection Association, in the US alone, more than 1.3 million fires were reported by fire departments in 2017, resulting in an estimated 3,400 civilian deaths, nearly 15,000 civilian injuries and $23 billion in property loss.

As these staggering numbers suggest, the use of flame retardants is as important as ever with the amount of electrical and electronic equipment and combustible material found in buildings and homes that increase the risk for fire hazards. Flame retardants refer to a variety of chemical compounds added to a wide range of combustible materials to create a layer of flammability protection and prevent fires from starting. Flame retardants also slow flame spread, providing more time to escape and for first responders to save lives and minimize property damage. Flame retardants are like an insurance policy you hope you never need; but you’re relieved you have when disaster strikes.

Flame retardants are essential to reducing the risks inherent in fire, which is why they’re found in so many products from home furnishings (upholstered furniture, curtains, carpet, mattresses, etc.) to transportation (automobile seats and components; airplane seats, carpet and walls; buses; trains, etc.) to plastics in consumer electronics to building and construction materials and more.

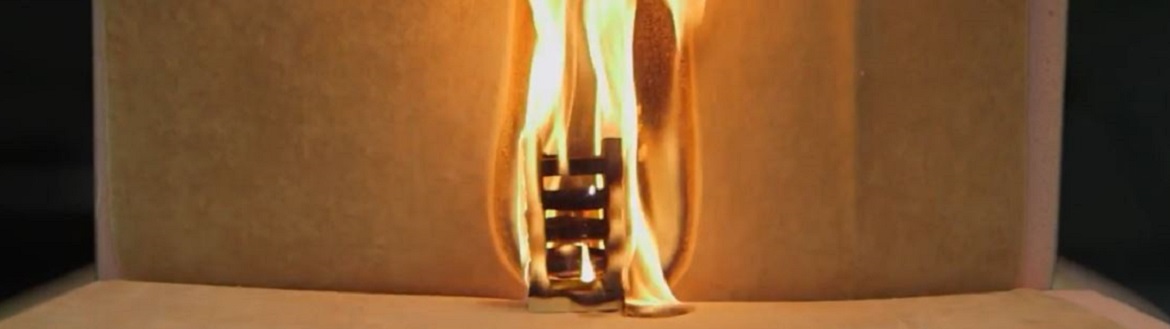

Fire is fueled by three things: heat, oxygen and fuel (combustible materials). If you take away any one of those elements from the “fire triangle,” the fire goes out. Flame retardants work in one of three ways to meet flame retardancy guidelines. They rely on chemical reactions that reduce the flammability of fuels or delay their combustion, or they blanket the oxygen fires need to spread. Fire retardants may also cool the fuel through physical action or endothermic chemical reactions.

When it comes to flame retardancy guidelines, there are many different tests and standards around the world for various applications. For example, the National Fire Protection Agency has more than 275 codes and standards. The Underwriters Laboratories (UL) certifies materials, systems and assemblies used for structural fire resistance and is the standard used by the Consumer Product Safety Commission.

There are also compliance issues, especially as the world of chemicals continues to evolve with increasing restrictions on what can be used. There are materials that were used for many years that are now outlawed because of environmental or health concerns (similar to the situation with the BPA-free trend in bottles). Compliance and regulation are major components of the flame retardant industry.

Products must meet EPA standards in the United States, REACH in Europe and various other standards around the world. There are also companies that have “do not use” lists of materials that can’t be used in their products because of liability issues or the perception that they aren’t safe. Because there is such a wide range of tests and standards globally, it’s important to work with a flame retardant chemical manufacturer that can navigate these disparate standards.

For formulators designing flame retardance into their products, there are many halogenated and non-halogenated polymer options available that can meet even the most stringent requirements (such as non-halogenated compounds in Europe) without impacting end-use properties. These polymers include next-generation thermoplastic polyurethanes (TPU), vinyl chloride and vinylidene chloride resins, nitrogen and phosphorus containing polymers and additives, brominated polyurethanes, and more.

Lubrizol has more than 50 years of experience developing a variety of flame retardant technologies and perfecting how to apply them across any number of products. Contact your Lubrizol account manager to learn more about how Lubrizol can collaborate with you to develop flame retardant polymers for even the most challenging applications while meeting diverse standards and regulations.