Digital printing has been around for several decades, particularly in home and office settings with small inkjet desktop printers. In commercial packaging, the label sector was an early adopter of digital technology. Only more recently have digital print platforms been catching on in other commercial printing applications like corrugated, carton, flexibles, direct-to-shape and even textiles. That’s because of advancements in industrial-scale inkjet technology and the ability to realize the advantages of just-in-time production, single-pass printing, personalization and shorter printing runs.

The growing use of digital printing can be seen in estimates for the digital printing packaging market, which is projected to grow from USD $30.2 billion in 2024 to USD $46.2 billion by 2029 at a compound annual growth rate of 8.9%.[1]

To help enable the move to digital printing and continued growth, digital ink technology has to deliver similar performance characteristics as analog printing, whether it’s print quality, adhesion, low migration inks, or the ability to be applied at high speeds with high throughput.

Implementing digital printing technology often means investing in an entire line, which can cost millions of dollars. Newly developed digital print presses include hundreds of inkjet printheads that are worth thousands of dollars each. The return on investment has to be compelling to make the move from analog to digital printing. Typically, the economics only work if there’s high output while still maintaining print quality and eliminating significant downtime.

The ink chemistry and design is critical to making the economics work. They have to provide high-quality, reliable, stable and compliant solutions that work across a range of materials and conditions. A key component of the ink formulation are highly stable pigment dispersions which enable high-speed, uninterrupted inkjet printing. They are designed to extend printhead life and maintain printer uptime to help ensure the overall success of an industrial inkjet printing ecosystem.

For water-based inks, drying speeds can prove a big challenge for formulators. Inks are required to have good 'open times' which prevents them drying out in and around the nozzles, however, they are also required to dry quickly once printed so that fast print speeds can be maintained. Humectants are typically used to keep the ink from drying out, but these have a negative impact on ink dry speeds. Dispersions that help keep inks 'open' in low humectant environments can be of great benefit. An increased open time is also important during press downtimes and can prevent having to go through the setup procedure again, saving time and money.

High Stability Pigment Dispersions

In packaging applications, stability under very high-speed printing is critical. Conventional dispersions based on standard polymeric dispersants can, over time, become de-anchored from the pigment surface, thus leading to re-agglomeration. Lubrizol's proprietary HSD dispersion technology uses reactive irreversible anchoring technology to fix the dispersant to the pigment surface to prevent this from happening. This irreversible dispersant anchoring technology provides strong electro-steric repulsion that maintains stability and resists sheer forces under high-speed application.

Following is an illustration showing the pigment encapsulated by the dispersant polymer using HSD dispersion technology:

With dispersions commercially available under the Diamond Dispersions™ brand name, Lubrizol HSD technology provides a larger region of stability that increases ink open time. The HSD technology creates a dispersion that is more stable to changes in solvent polarity and allows for more formulating latitude in the ink formulation. These dispersions also eliminate jetting problems and blocked nozzles.

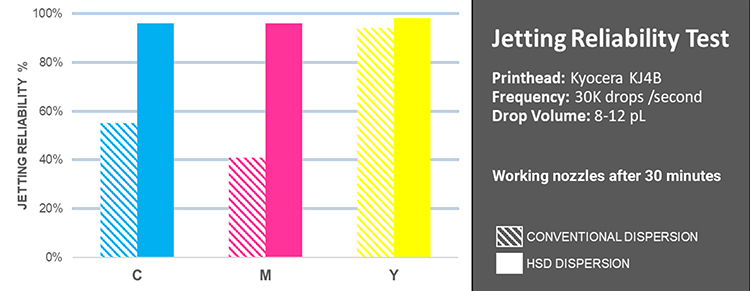

Stability is demonstrated through real-world application and testing. In this jetting reliability test using a Kyocera KJ4B printhead with a jetting frequency of 30,000 drops per second, inks based on HSD technology perform significantly better than those based on a conventional dispersion in regard to the percent nozzle drop out after 30 minutes of continuous jetting.

Diamond Dispersions™ color dispersions enable the transition from analog to digital printing by providing exceptional ink stability, print performance and color fastness properties in a wide range of digital ink formulations and end applications, including packaging and textiles. This includes in single-pass printers designed for high-speed print applications. Highly stable pigment dispersions are designed to extend printhead life and maintain printer uptime to help ensure the overall success of an industrial inkjet printing ecosystem.

Synergizing the Full System

Lubrizol has extensive experience in analog package printing, including with food-compliance printing in food packaging. That experience translates into digital printing with continuous development of products that enable high-speed, high-definition printing across a wide range of applications.

Lubrizol provides all the primary chemical components needed to synergize the full system—color dispersions, dispersants, jettable resins, binders, surface modifiers and ink receptive coatings. Through this complete understanding of how the many parts interact with one another, Lubrizol can help optimize the entire print system.

Contact us to learn more about how the Diamond Dispersions brand of advanced water-based pigmented ink dispersions deliver the critical performance required for complex digital inks.

[1] Digital Printing Packaging Market, Markets and Markets: https://www.marketsandmarkets.com/Market-Reports/digital-printing-packaging-market-249244591.html