TempRite® Engineered Materials specialise in chlorinated polyvinyl chloride (CPVC), a highly durable material that stands up to the elements in many outdoor scenarios:

- Construction of residential, commercial and institutional buildings

- Architectural design for exterior facades and cladding

- Automotive industry

- Boating and marine industry

The Threat of UV

UV (Ultraviolet) is electromagnetic radiation; while invisible to the human eye, it is arguably the biggest hurdle product engineers face when developing materials for outdoor use. Not only does it pose a threat of degradation to structures; we as humans are degraded by UV also. UV is harmful because it generates free radicals. Free radicals are a highly reactive form of a chemical with an unpaired electron in its structure. Free radicals will attack anything in their path in order to pair that electron. With many materials, such as polypropylene and polystyrene, this results in hydrogen abstraction and chain cleavage, breaking the polymer molecule down into smaller and smaller pieces.What Gives CPVC UV Resistance

CPVC is actually created in a free radical chlorination process. UV is utilized to generate chlorine free radicals which attach themselves to the PVC starting material by abstracting hydrogen. The chlorine on the molecular chain however, helps to stabilize it against chain cleavage, preventing it from breaking down into smaller pieces.

UV Absorption

Most CPVC compounds are formulated with titanium dioxide. It is a strong defence against the threat of UV in three ways:

It scatters sunlight, preventing penetration.

It absorbs electromagnetic energy without creating a free radical inside the polymer.

It provides opacity and thus makes it difficult for UV to penetrate. Many alternative polymers are clear or translucent. This can be a problem for polyethylene for example, as sunlight affects more than just the surface, penetrating deeper into the material, creating free radicals throughout.

Application 1 - Residences and Commercial Buildings

- Thermal expansion resistance

- Can be coextruded with acrylic

- Cost effective alternative to metal and wood

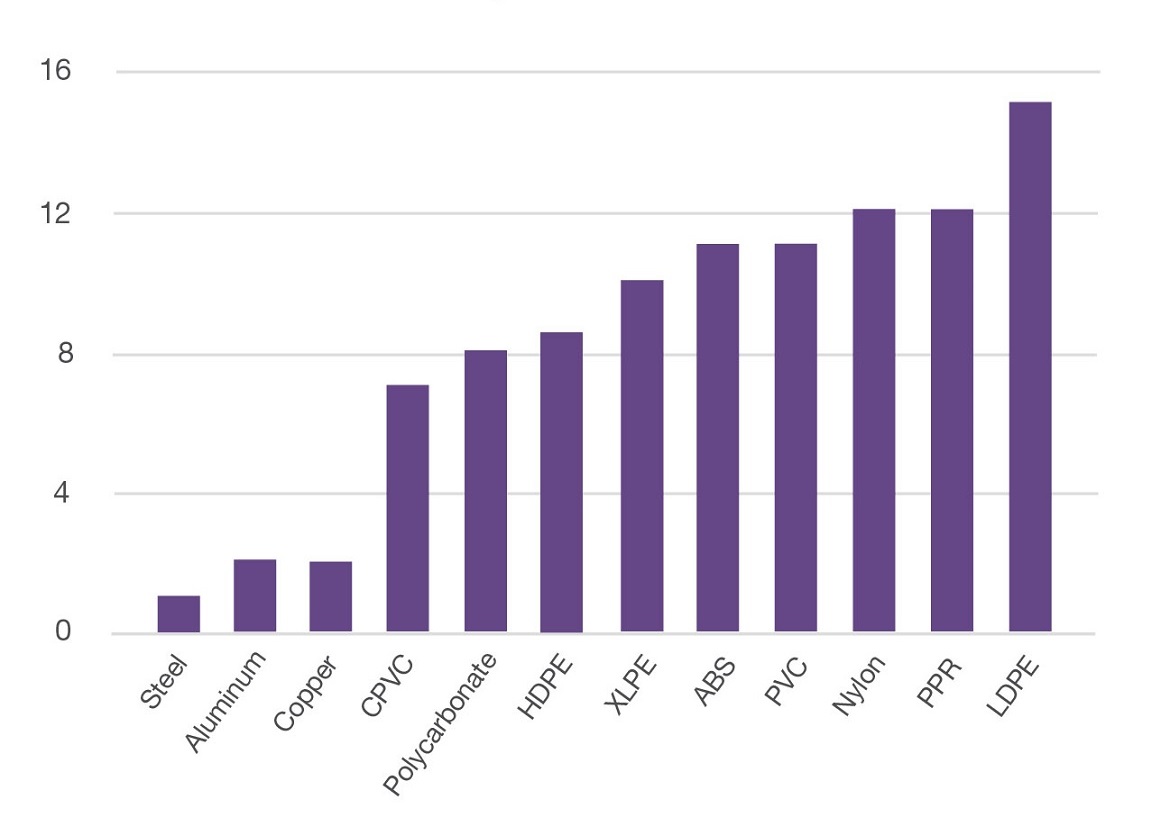

A constant threat to the integrity of outward facing walls is thermal expansion, causing unsightly warping. CPVC can be extruded into very large parts for external construction.

It is recommended particularly for its low thermal expansion. CPVC has the lowest thermal expansion of all commonly used plastics in the construction industry. It is an ideal choice as a metal or wood alternative, offering a cost effective solution for house sidings, as well as long term durability.

CPVC can be coextruded with weatherable acrylic capstock if necessary. This is a thin layer of acrylic, extruded together with CPVC for extra added resistance to UV. This can extend the life of house cladding by decades.

Thermal Expansion of Materials

Application 2 - Windows and Doors

- Energy efficient

- Compatibility with ancillary materials

- Design flexibility

A sustainable, effective choice for window profiles and doors

Application 3 - Automotive Industry

- Acid rain resistant

- Ozone resistant

- Works well with electrical machinery

CPVC’s resistance to these common outdoor pollutants in our atmosphere enable them for effective use in the automotive industry where emissions are still very much present in global transportation.

Application 4 - Aquatic Environments

- Hydrolysis resistant

- Resistant to NOx emissions

CPVC is resistant to hydrolysis, a degradation reaction in which water depolymerizes the material, causing molecular bonds to break. Polymers susceptible to hydrolysis include polyester, nylon, polyurethane and polycarbonate.

In the presence of water, CPVC’s molecular structure is not under threat, allowing engineers to extrude panels for marine transportation or piping for water distribution.

Marine transportation, which is notoriously responsible for NOx emissions, is another useful application for CPVC, for its resistance to this common pollutant.

Application 5 - Architecture

- Design flexibility

- Resistant to radiant heating

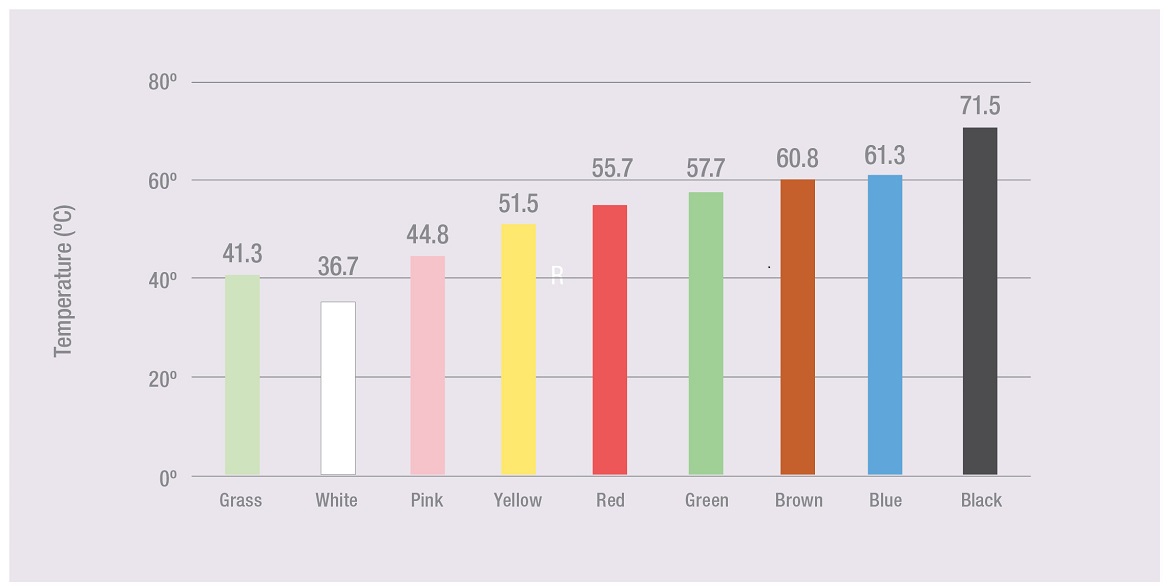

Product designers aiming to achieve a specific finish for an outdoor application are too often limited by colour, due to radiant heating in sunlight.

Many polymers with lower softening temperatures are limited in the colours they can be made in if the final product will be exposed to sunlight.. Darker shades can push polymer temperatures over their limit, threatening their integrity, strength, and overall performance.

CPVC maintains its mechanical strength outdoors. This is particularly useful for designers who want to use more variety of color without compromising on performance.

CPVC can be used anywhere the natural and man-made corrosive elements of the outdoors traditionally cause degradation in materials. Talk to a TempRite Engineered Materials expert today, to discuss applying CPVC to your outdoor product development for long lasting strength and performance.