As a worldwide leader in advanced materials and the inventor of thermoplastic polyurethane (TPU), Lubrizol is proud to expand our expertise and capabilities with the addition of Avid Product Development. Since acquiring Avid Product Development in 2020, Lubrizol is proud to combine capabilities between both companies to deliver truly differentiated solutions that accelerate the growth of industries adopting and using 3D printing.

Going beyond traditional 3D printing service providers, Avid features strong design for additive manufacturing (DfAM), printing, and post-processing capabilities. Allowing Avid to help customers achieve scalable product design, prototyping, and additive manufacturing results.

To illustrate their commitment to quality, DfAM, 3D printing, and post-processing capabilities, Avid developed a sample kit that highlights the differentiated solutions that help their customers break barriers and accelerate the growth of 3D printing in key industries.

INSIDE THE KIT

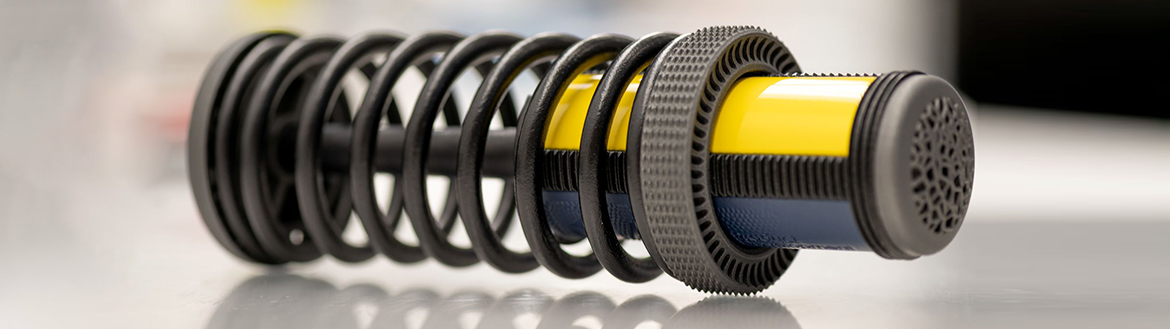

Shock Absorber

With interchangeable springs, this interactive shock absorber demonstrates the effects design has on part performance. The interoperability of various 3D printing materials and parts with distinct features and finishes, also exemplifies the endless design possibilities with additive manufacturing (AM).

The pre-assembled shock absorber includes a traditional coil spring 3D printed in PA11 and multiple components produced in PA12. The surface of the spring is vapor smoothed and the shock body features uniquely designed panels finished with various post-processing techniques for improved aesthetics and part quality.

Spring Bellows

Manufactured in ESTANE® 3D TPU M95A, the spring bellows provides exceptional rebound and low levels of permanent deformation following prolonged periods of compression.

Concept Spring

Showcasing the ability of additive manufacturing to create complex parts not possible through conventional methods, this concept spring utilizes design for additive manufacturing and generative design tools to alter the already versatile performance of ESTANE® TPU M95A.

Custom Packaging

Leveraging the design freedom of additive manufacturing, this custom protective case features a unique viewing window with a lattice structure printed in ESTANE® TPU M95A, a non-marring material suitable for Class A surfaces and other high-value finishes. Utilizing a DfAM approach also allowed for part consolidation with a living hinge made as one piece and a secure snap fit closure.

Electronics Enclosure

Highlighting the value of additive manufacturing for low to mid volume printed circuit board (PCB) housings, this electronics enclosure features an integrated button and a multi-material design in ultra-clear resin PA12 for enhanced visual appeal. Electronic device designed and assembled by Avid Product Development.

In-House Capabilities

These sample parts serve as only a glimpse into the capabilities with Lubrizol and Avid.