ESTANE® 3D TPU M95A has proven to deliver superior performance capabilities like flexibility/elongation, temperature and abrasion resistance that the additive manufacturing industry can depend on. But Lubrizol 3D Printing Solutions wanted to determine if the material could deliver even more.

Understanding that chemical resistance is critical to material performance in various industries, Lubrizol 3D Printing Solutions put ESTANE 3D TPU M95A to the test against a wide range of chemicals for a four-week period.

The Testing of ESTANE 3D TPU M95A

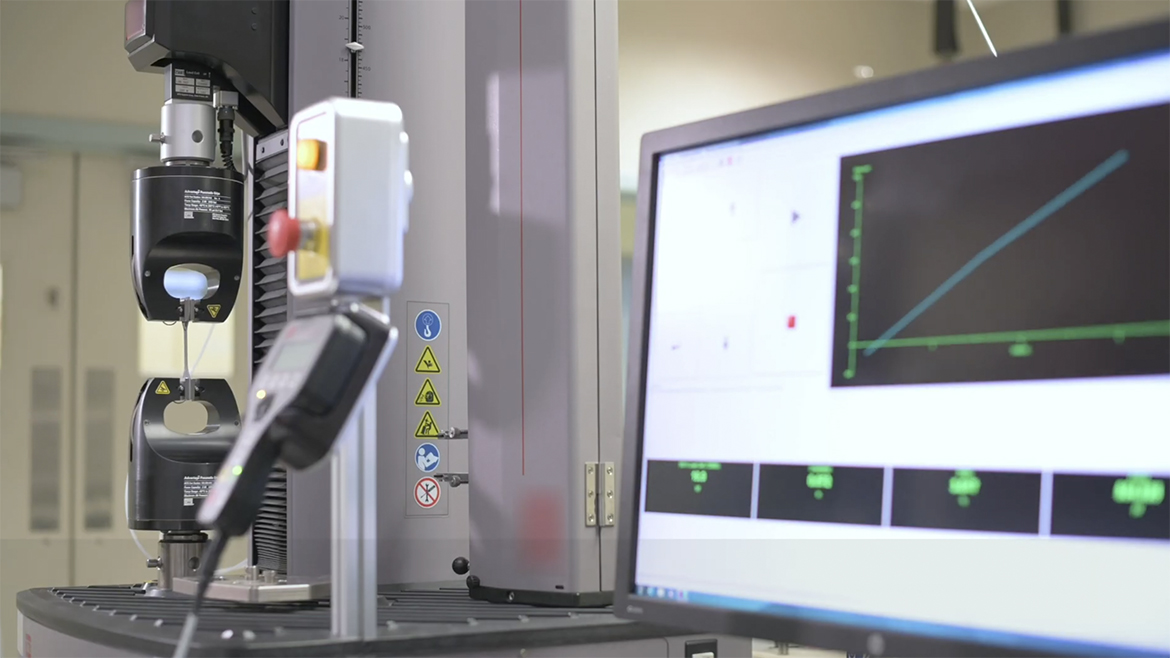

To evaluate the chemical resistance of ESTANE 3D TPU M95A, Lubrizol 3D Printing Solutions immersed 3D printed tensile parts in a variety of chemicals, ranging from 3% hydrogen peroxide to gasoline. To test the chemical resistance of the material, the parts were submerged in individual containers of chemicals for four weeks.

Following the four-week exposure, the ESTANE 3D TPU M95A parts were wiped clean and evaluated by the Lubrizol Measurement Science Group by measuring the ultimate tensile strength (UTS) and the volume swell (or volume change). A rating of 1 indicated little to no adverse effect on the material and a rating of 4 indicated substantial material changes.

The Results

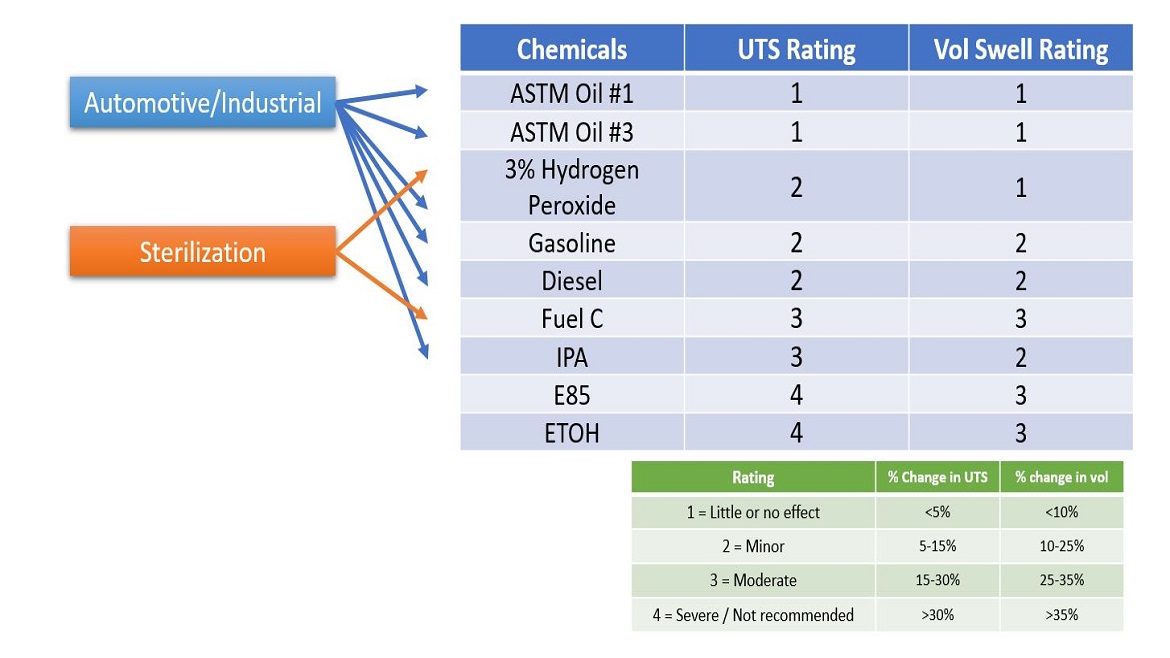

The test results prove that ESTANE 3D TPU M95A presents a strong resistance to chemicals commonly found within automotive and industrial settings. With levels of change to UTS and volume swell ratings as low as under 5%, ESTANE 3D TPU M95A proves to be an excellent choice for maintaining performance in many harsh chemical environments

However, that does not limit ESTANE 3D TPU M95A from only being used within these specific industry applications. Although there was a higher UTS and volume swell ratings found when exposed to different harsh chemicals like E85, ESTANE 3D TPU M95A can potentially still be used for applications that require less extensive exposure to that specific chemical. An example of a more minimal interaction of the material and the chemical would be heavy-duty packaging, jigs for car door assembly and PPE masks.

For further insight into the performance of ESTANE 3D TPU M95A when immersed in specific chemicals for four weeks, please reference the table below:

The Industry Choice

By testing the chemical resistance of ESTANE M95A, Lubrizol 3D Printing Solutions is proud to offer an excellent material choice to our customers that will positively impact a variety of industries.

To discover how ESTANE 3D TPU M95A could be used for a specific application, contact a representative at Lubrizol 3D Printing Solutions today.

Picture in the banner courtesy of Forerunner 3D