Our most common piece of feedback on ESTANE® 3D TPU M95A is how easy it is to unpack a 3D printed part. Instantly, customers discover an ease of unpacking similar to what you’d expect when removing a part made with PA12 as opposed to a typical elastomeric material. As the only TPU (thermoplastic polyurethane) available for use in the HP Multi Jet Fusion™ 4200 series 3D printing solution, ESTANE® 3D TPU M95A excels in delivering a wide range of capabilities while maintaining speed and efficiency all the way through the unpacking process.

The time savings is significant, to say the least.

As the one who’s responsible for the productivity of our printing processes, I really appreciate how efficient ESTANE M95A makes unpacking,” says Kyle Jones, Shop & Quality Control Manager with Avid Product Development, a Lubrizol Company. Avid is an industry leader in 3D design, prototyping and manufacturing. “I actually look forward to unpacking ESTANE M95A prints,” he continues. “Our unpacking time is about half what we expected. It’s really easy to brush or shake off the extra powder with very little effort.

As Jones explains, the time savings of ESTANE® 3D TPU M95A extends beyond the unpacking itself to the cleanup of the printer. “The powder tends to be a simple to vacuum,” he claims. “It doesn’t build up too much in all the usual places, like printheads and filters. Clean-up is an easy process with this material.

See for yourself.

Watch this short video to see just how efficiently parts made with ESTANE® M95A can be unpacked. The more you’ve worked with unpacking other elastomeric materials,” claims Jones, “the more impressed you’re likely to be.

A wide-open window for unpacking.

The ease of unpacking different materials varies with different temperatures. Sometimes when a material cools down too much, the unused material tends to stick to the part and reheating is required to aid in its removal. With ESTANE® 3D TPU M95A, that’s not a typical issue. “We don’t have to worry about scheduling the builds and unpacking so precisely with this material,” says Jones. “It gives us a lot more flexibility in terms of how, and more importantly, when we do things.

Easier unpacking enables more complex designs.

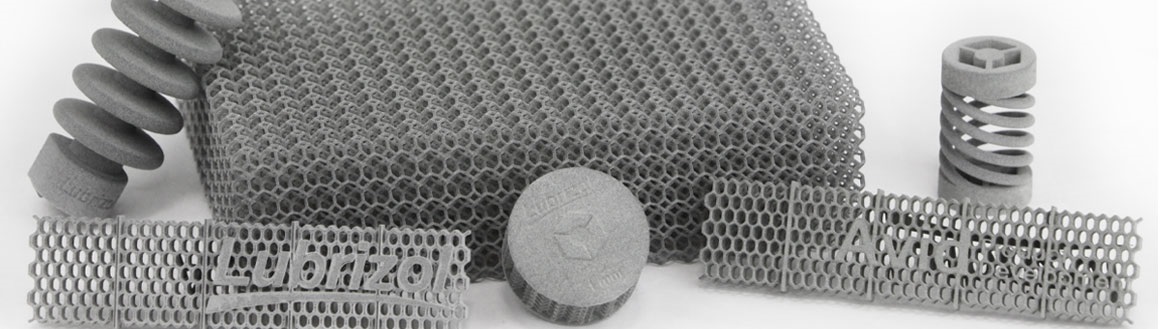

While 3D printers are capable of producing incredibly intricate parts, some of the more complex designs can be time-consuming, if not impossible, to unpack. “We’ve seen some complicated lattice structures which were virtually unfeasible when it came to post processing,” recounts Jones. “Removing the residual material was far too labor intensive to be practical.

In contrast, users of ESTANE® 3D TPU M95A are discovering much more design freedom. “Because the powder so easily brushes off of ESTANE M95A parts, you can design in things like blind holes, incredible lattices or almost any realistic internal geometry without creating a huge headache in unpacking,” states Jones. Additionally, when the powder can be removed from intricate parts with this level of ease, damaging parts during unpacking is far less likely. “This is essential,” says Jones. “Maintaining the integrity of the part is paramount in achieving a high level of productivity and profitability.

Optimized material recycling.

Before a material can be recycled, it must be reclaimed--another area in which ESTANE® 3D TPU M95A is setting the bar high. Because the unused powder falls away from parts so freely, it’s easier to reclaim and reuse more of the material. This is a key benefit since this material allows for every new build to be made with up to 80% recycled powder. This feature, coupled with the other attributes already mentioned, is what can make ESTANE M95A such a cost-effective material choice.

The one benefit that enables all others.

Clearly, ESTANE® 3D TPU M95A boasts some extraordinary performance characteristics. Yet, having the ability to create parts with strong heat and abrasion resistance, high tensile strength, exceptional compression recovery and intricate structures wouldn’t mean a whole lot if you couldn’t effectively remove the printed parts from the powder. Which is why amid its many other impressive characteristics, excellent unpacking ease may be the most fundamental benefit of ESTANE M95A of all. In addition, ESTANE® 3D TPU M95A has skin contact approval for certain applications.

Add the element of speed to your 3D print processing.

If you’re looking for every opportunity to increase the efficiency of your 3D printing operations, making significant gains in the unpacking process can pay huge dividends in your overall productivity. Time is money, and ESTANE® 3D TPU M95A may be able to help you save both in your applications. To learn more or to request a material TDS, please contact our 3D Printing Solutions team.